ACI has the potential to achieve moderate to high levels of Hg control. The performance of an activated carbon is related to its physical and chemical characteristics. Generally, the physical properties of interest are surface area, pore size distribution, and particle size distribution. The capacity for Hg capture generally increases with increasing surface area and pore volume. The ability of Hg and other sorbates to penetrate into the interior of a particle is related to pore size distribution. The pores of the carbon sorbent must be large enough to provide free access to internal surface area by Hg0 and Hg2+ while avoiding excessive blockage by previously adsorbed reactants. As particle sizes decrease, access to the internal surface area of particle increases along with potential adsorption rates.

Carbon sorbent capacity is dependent on temperature, the concentration of Hg in the flue gas, the flue gas composition, and other factors. In general, the capacity for adsorbing Hg2+ will be different than that for Hg0.The selection of a carbon for a given application would take into consideration the total concentration of Hg, the relative amounts of Hg° and Hg2+, the flue gas composition, and the method of capture [electrostatic precipitator (ESP), FF, or dry FGD scrubber].

ACI may be used either in conjunction with existing control technologies and/or with additional control such as the addition of an FF. To date ACI has only been evaluated during short-term tests on commercially operating electrical generating plants. Longer-term tests of ACI have been limited to continuous operation, 24 hr/day-7days/week, for a period of less than two weeks at four field test sites. Also, combustion modification, such as coal reburning technology, may increase the carbon in fly ash and yield enhanced Hg capture in PM control devices

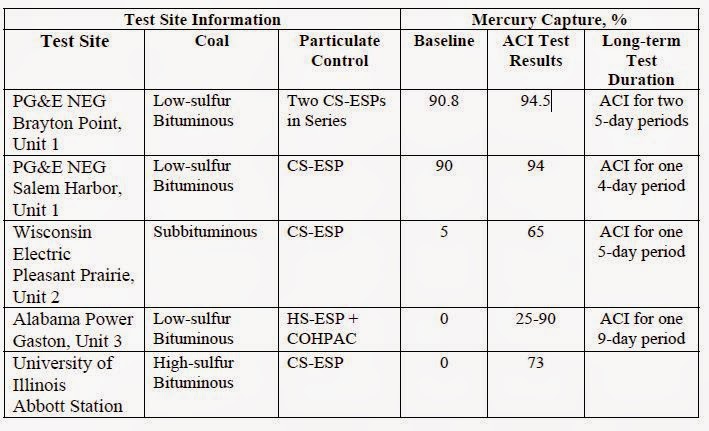

The Department of Energy/National Energy Technology Laboratory (DOE/NETL), the Electric Power Research Institute (EPRI) and a group of utility companies have funded projects to evaluate the use of ACI as summarized in Table 2. The Hg removal via ACI is measured between the inlet and outlet of the particulate matter control device. Note that these projects represent ACI applications that can be used to control Hg emissions from units that (1) are currently equipped with an ESP, and (2) burning bituminous or subbituminous coals. The tests at Alabama’s Gaston Plant show the potential Hg control levels that can be achieved by installing a compact hybrid particulate collector (COHPAC) or small pulse-jet FF downstream of an existing ESP and injecting activated carbon upstream of the COHPAC unit.

The average baseline removal efficiency across both ESPs averaged 90.8 percent, as measured during three tests with the OH method. During parametric tests, a variety of activated carbons, including Darco-FGD, were injected just downstream of the first ESP. Incremental Hg removal efficiencies across the second ESP ranged from 3 to 93 percent depending on the carbon injection concentration. Total average Hg removal efficiencies across both ESPs as determined by the S-CEMs averaged 94.5 percent during injection of Darco-FGD at 10 lb/MMacf.

Longer-term performance tests involved the continuous injection of Darco-FGD 24 hours/day for 10 days at two different injection concentrations. Five days of injection at 10 μg/dncm was followed by five days of injection at 20 μg/dncm. The average removal efficiency across both ESPs during ACI concentrations of 10 lb/MMacf was 94.5 percent as measured during 3 OH method tests. These high Hg capture efficiencies are considered to be atypical of other CS-ESP units because of the high UBC concentrations, the two ESPs, and the long duct runs.

Salem Harbor

Tests were conducted on Unit 1, an 88 MW single wall-fired unit which is equipped with low-NOx burners, a selective noncatalytic reduction (SNCR) system for NOx control and a CS-ESP. Salem Harbor fires a South American low-sulfur bituminous coal with 0.03-0.08 ppm Hg and 206 ppm chlorine. The resulting fly ash had an LOI of 20 to 30 percent.

Parametric tests at reduced loads that lowered fly ash LOI to 15 to 20 percent did not significantly reduce Hg capture. Increasing the ESP inlet temperature from 300°F to 350°F reduced Hg removal from approximately 90 percent to the 10-20 percent range. The effects of changes in LOI over test range of 15 to 30 percent were not as strong as the effects of temperature changes.

During November 2002, four days of long-term sorbent injection tests were conducted with Darco-FGD at an injection concentration of 10 lb/MMacf. The average Hg capture efficiency during 3 OH tests was 94.0 percent. The Hg0 concentrations for all inlet and outlet samples were below the method detection limit. More than 95 percent of the total inlet Hg was measured as Hgp, indicating nearly complete in-flight capture of Hg upstream of the ESP. The very high in-flight Hg capture by the UBC in fly ash and injected activated carbon are not believed to be representative of plants equipped with a CS-ESP.

Pleasant Prairie

ACI testing was conducted on the 600-MW Unit 2, which fired a PRB coal with 0.11 ppm Hg and 8 ppm chlorine. The unit is equipped with an ESP. Testing was conducted on one ESP chamber (1/4 of the unit). The plant sells its fly ash for use in concrete.

Baseline tests using the OH method exhibited Hg capture in the ESP of about 5 percent with more than 70 percent of the Hg at the ESP inlet being Hg0. Major parametric test variables included sorbent properties and sorbent injection concentration. At low ACI concentrations, Hg reductions across the ESP were higher than expected, reaching 60 to 65 percent at injection concentrations near 10 lb/MMacf. Increasing sorbent injection concentrations to 20 to 30 lb/MMacf increased Hg reduction efficiencies to only about 70 percent. Subsequently, in long-term tests carbon was injected continuously at 24 h/day for 5 days. OH measurements confirmed that about 60-70% mercury removal could be achieved at a carbon injection concentration of 10 lb/MMacf.

Gaston

ACI testing was conducted on the 270-MW Unit 3, which fired low-sulfur eastern bituminous coals with 0.14 ppm Hg and 160 ppm chlorine. The unit is equipped with low-NOx burners, a HS-ESP and a COHPAC, which was retrofit earlier to capture residual fly ash escaping the ESP. Testing was conducted on one-half of the flue gas stream.

Baseline test results showed that neither the HS-ESP nor COHPAC captured a significant amount of Hg. During ACI parametric tests, Hg capture efficiencies ranged from 25 to more than 90 percent, depending on the carbon injection rate. ACI concentrations of 3 lb/MMacf resulted in gas-phase Hg reductions greater than 90 percent across the COHPAC. However, it was determined that ACI resulted in a significant increase in COHPAC cleaning frequency. The different activated carbons used in the parametric tests produced Hg capture efficiencies similar to Darco-FGD, the benchmark sorbent. Differences in sorbent particle size or base material (bituminous coal or lignite) did not result in appreciable performance differences. Subsequently, in long-term tests, carbon was injected continuously at 24 h/day for 9 days. The COHPAC cleaning frequency and ACI rate was kept at a reduced level to avoid adverse impacts on COHPAC bag life. Relatively short duration OH measurements reflected about 90% removal of mercury, but measurements taken with S-CEMS reflected about 78% removal over the period of the long-term testing.

Abbott

In the summer of 2001, EPRI sponsored ACI tests at the Abbott Power Plant located in Champaign, Illinois. Unit 5, the test unit, is a stoker-fired unit followed by air heater and a CS-ESP. During the tests, Unit 5 burned an Illinois Basin coal with nominal sulfur and chlorine contents of 3.8 and 0.25%, respectively. Activated carbons used during the parametric tests included Darco FGD, fine FGD (size segregated Darco FGD), and an experimental Corn Char sorbent.

During the parametric tests ACI concentrations were varied from 5.1 to 20.5 lb/MMacf. The ESP inlet temperatures ranged from 340 to 390 °F. The performance of Darco FGD and the corn char sorbents were similar, showing increases in Hg capture proportional to the ACI concentration. The fine FGD sorbent exhibited improved performance relative to the standard FGD. The best performance, 73% Hg capture, was achieved by injection of fine FGD at 13.8 lb/MMacf at an ESP inlet temperature of 341 °F. The high sulfur flue gas appeared to impair the performance of the activated carbon. This is consistent with bench-scale research that shows that high SO2 concentrations diminished the adsorption capacity of activated carbons.

Recently, EPA has estimated cost for ACI-based controls.1 These estimates range from 0.03-3.096 mills/kWh. However, the higher costs are usually associated with the plant configuration utilizing SDA+CS-ESP or HS-ESPs. Excluding the costs associated with the plant configurations involving SDA + ESP or HS-ESP, cost estimates are from 0.03 to 1.903 mills/kWh. At the low end of this cost range, 0.03 mills/kWh, it is assumed that no additional control technologies are needed, but mercury monitoring will be necessary.

RD&D Needs for Sorbent Injection Systems

In order to enhance the cost effective capture of Hg by ACI, and other sorbent injection systems, for the important coal type/retrofit control combinations, the following RD&D efforts are needed.

• Research efforts on Hg speciation and capture should be continued. These efforts will include bench- and pilot-scale investigations on the effects of flue gas composition, fly ash properties (UBC content and catalytic metal content), flue gas quench rates, and other important parameters. Speciation and capture computer models must be developed to evaluate field test results and for application to other utility sites.

• Development and demonstration of low cost sorbents, impregnated sorbents and innovative sorbents that are effective in controlling Hg emissions from subbituminous coal and lignite should continue. High temperature sorbents for use with HS-ESPs also should be investigated.

• Development and demonstration of techniques to improve Hg capture in units equipped with an ESP, SDA/ESP or SDA/FF and burn subbituminous coal and lignite is needed. This will include evaluation of coal blending, combustion modifications, use of oxidizing reagents, and use of impregnated sorbents.

• Evaluation and demonstration of cost-effective ESP retrofit approaches including installation of ducting to increase residence times and use of circulating fluidized bed absorbers for optimal utilization of sorbents should be conducted. The use of multipollutant sorbents that capture SO2 and Hg should also be investigated.

• Determination and demonstration of optimum design and operating conditions for COHPAC applications on a range of boiler operating conditions is needed. This will include evaluation of the effects of air-to-cloth ratios, fabric filter material, cleaning frequencies, and baghouse arrangements on Hg capture. COHPAC-based tests should be conducted with both mercury and multipollutant sorbents.

• Continued evaluation of potential leaching or re-emission of mercury from sorbent/ash residues that are disposed of or utilized is needed.

Carbon sorbent capacity is dependent on temperature, the concentration of Hg in the flue gas, the flue gas composition, and other factors. In general, the capacity for adsorbing Hg2+ will be different than that for Hg0.The selection of a carbon for a given application would take into consideration the total concentration of Hg, the relative amounts of Hg° and Hg2+, the flue gas composition, and the method of capture [electrostatic precipitator (ESP), FF, or dry FGD scrubber].

ACI may be used either in conjunction with existing control technologies and/or with additional control such as the addition of an FF. To date ACI has only been evaluated during short-term tests on commercially operating electrical generating plants. Longer-term tests of ACI have been limited to continuous operation, 24 hr/day-7days/week, for a period of less than two weeks at four field test sites. Also, combustion modification, such as coal reburning technology, may increase the carbon in fly ash and yield enhanced Hg capture in PM control devices

The Department of Energy/National Energy Technology Laboratory (DOE/NETL), the Electric Power Research Institute (EPRI) and a group of utility companies have funded projects to evaluate the use of ACI as summarized in Table 2. The Hg removal via ACI is measured between the inlet and outlet of the particulate matter control device. Note that these projects represent ACI applications that can be used to control Hg emissions from units that (1) are currently equipped with an ESP, and (2) burning bituminous or subbituminous coals. The tests at Alabama’s Gaston Plant show the potential Hg control levels that can be achieved by installing a compact hybrid particulate collector (COHPAC) or small pulse-jet FF downstream of an existing ESP and injecting activated carbon upstream of the COHPAC unit.

A mobile sorbent injection system and a mobile test laboratory were constructed for use at all test sites except Abbott. Norit lignite-based carbon, Darco-FGD, was used as the benchmark sorbent at all test sites. Tests at the sites generally included:

• the use of Apogee Scientific semi-continuous emission monitors (S-CEMs) for measurement of Hg0 and total vapor-phase Hg (Hgv);

• periodic measurements of Hgp, Hg2+ and Hg0 with the Ontario-hydro (OH) method;

• laboratory and slipstream sorbent screening tests;

• baseline tests without the use of sorbents;

• parametric tests to evaluate the effects of process conditions and sorbent variables; and

• 4- to 9-day tests with Darco-FGD.

The purpose of tests at each site was to determine the performance and costs of activated carbon sorbents for controlling Hg emission from coal-fired electrical generating plants equipped only with an ESP. The field tests are summarized below.

Brayton Point

ACI testing was conducted on the 245-MW Unit 1, which fired a low-sulfur bituminous coal with 0.03 ppm Hg and 2000-4000 ppm chlorine. The unit is equipped with low-NOx burners and typically has high levels of unburned carbon (UBC) in the fly ash as indicated by loss on ignition (LOI) measurements. The PM control system at the unit is unusual in that it consists of two CS-ESPs in series and long duct runs. Carbon was injected between the ESPs.

The average baseline removal efficiency across both ESPs averaged 90.8 percent, as measured during three tests with the OH method. During parametric tests, a variety of activated carbons, including Darco-FGD, were injected just downstream of the first ESP. Incremental Hg removal efficiencies across the second ESP ranged from 3 to 93 percent depending on the carbon injection concentration. Total average Hg removal efficiencies across both ESPs as determined by the S-CEMs averaged 94.5 percent during injection of Darco-FGD at 10 lb/MMacf.

Longer-term performance tests involved the continuous injection of Darco-FGD 24 hours/day for 10 days at two different injection concentrations. Five days of injection at 10 μg/dncm was followed by five days of injection at 20 μg/dncm. The average removal efficiency across both ESPs during ACI concentrations of 10 lb/MMacf was 94.5 percent as measured during 3 OH method tests. These high Hg capture efficiencies are considered to be atypical of other CS-ESP units because of the high UBC concentrations, the two ESPs, and the long duct runs.

Salem Harbor

Tests were conducted on Unit 1, an 88 MW single wall-fired unit which is equipped with low-NOx burners, a selective noncatalytic reduction (SNCR) system for NOx control and a CS-ESP. Salem Harbor fires a South American low-sulfur bituminous coal with 0.03-0.08 ppm Hg and 206 ppm chlorine. The resulting fly ash had an LOI of 20 to 30 percent.

Parametric tests at reduced loads that lowered fly ash LOI to 15 to 20 percent did not significantly reduce Hg capture. Increasing the ESP inlet temperature from 300°F to 350°F reduced Hg removal from approximately 90 percent to the 10-20 percent range. The effects of changes in LOI over test range of 15 to 30 percent were not as strong as the effects of temperature changes.

During November 2002, four days of long-term sorbent injection tests were conducted with Darco-FGD at an injection concentration of 10 lb/MMacf. The average Hg capture efficiency during 3 OH tests was 94.0 percent. The Hg0 concentrations for all inlet and outlet samples were below the method detection limit. More than 95 percent of the total inlet Hg was measured as Hgp, indicating nearly complete in-flight capture of Hg upstream of the ESP. The very high in-flight Hg capture by the UBC in fly ash and injected activated carbon are not believed to be representative of plants equipped with a CS-ESP.

Pleasant Prairie

ACI testing was conducted on the 600-MW Unit 2, which fired a PRB coal with 0.11 ppm Hg and 8 ppm chlorine. The unit is equipped with an ESP. Testing was conducted on one ESP chamber (1/4 of the unit). The plant sells its fly ash for use in concrete.

Baseline tests using the OH method exhibited Hg capture in the ESP of about 5 percent with more than 70 percent of the Hg at the ESP inlet being Hg0. Major parametric test variables included sorbent properties and sorbent injection concentration. At low ACI concentrations, Hg reductions across the ESP were higher than expected, reaching 60 to 65 percent at injection concentrations near 10 lb/MMacf. Increasing sorbent injection concentrations to 20 to 30 lb/MMacf increased Hg reduction efficiencies to only about 70 percent. Subsequently, in long-term tests carbon was injected continuously at 24 h/day for 5 days. OH measurements confirmed that about 60-70% mercury removal could be achieved at a carbon injection concentration of 10 lb/MMacf.

Gaston

ACI testing was conducted on the 270-MW Unit 3, which fired low-sulfur eastern bituminous coals with 0.14 ppm Hg and 160 ppm chlorine. The unit is equipped with low-NOx burners, a HS-ESP and a COHPAC, which was retrofit earlier to capture residual fly ash escaping the ESP. Testing was conducted on one-half of the flue gas stream.

Baseline test results showed that neither the HS-ESP nor COHPAC captured a significant amount of Hg. During ACI parametric tests, Hg capture efficiencies ranged from 25 to more than 90 percent, depending on the carbon injection rate. ACI concentrations of 3 lb/MMacf resulted in gas-phase Hg reductions greater than 90 percent across the COHPAC. However, it was determined that ACI resulted in a significant increase in COHPAC cleaning frequency. The different activated carbons used in the parametric tests produced Hg capture efficiencies similar to Darco-FGD, the benchmark sorbent. Differences in sorbent particle size or base material (bituminous coal or lignite) did not result in appreciable performance differences. Subsequently, in long-term tests, carbon was injected continuously at 24 h/day for 9 days. The COHPAC cleaning frequency and ACI rate was kept at a reduced level to avoid adverse impacts on COHPAC bag life. Relatively short duration OH measurements reflected about 90% removal of mercury, but measurements taken with S-CEMS reflected about 78% removal over the period of the long-term testing.

Abbott

In the summer of 2001, EPRI sponsored ACI tests at the Abbott Power Plant located in Champaign, Illinois. Unit 5, the test unit, is a stoker-fired unit followed by air heater and a CS-ESP. During the tests, Unit 5 burned an Illinois Basin coal with nominal sulfur and chlorine contents of 3.8 and 0.25%, respectively. Activated carbons used during the parametric tests included Darco FGD, fine FGD (size segregated Darco FGD), and an experimental Corn Char sorbent.

During the parametric tests ACI concentrations were varied from 5.1 to 20.5 lb/MMacf. The ESP inlet temperatures ranged from 340 to 390 °F. The performance of Darco FGD and the corn char sorbents were similar, showing increases in Hg capture proportional to the ACI concentration. The fine FGD sorbent exhibited improved performance relative to the standard FGD. The best performance, 73% Hg capture, was achieved by injection of fine FGD at 13.8 lb/MMacf at an ESP inlet temperature of 341 °F. The high sulfur flue gas appeared to impair the performance of the activated carbon. This is consistent with bench-scale research that shows that high SO2 concentrations diminished the adsorption capacity of activated carbons.

Recently, EPA has estimated cost for ACI-based controls.1 These estimates range from 0.03-3.096 mills/kWh. However, the higher costs are usually associated with the plant configuration utilizing SDA+CS-ESP or HS-ESPs. Excluding the costs associated with the plant configurations involving SDA + ESP or HS-ESP, cost estimates are from 0.03 to 1.903 mills/kWh. At the low end of this cost range, 0.03 mills/kWh, it is assumed that no additional control technologies are needed, but mercury monitoring will be necessary.

RD&D Needs for Sorbent Injection Systems

In order to enhance the cost effective capture of Hg by ACI, and other sorbent injection systems, for the important coal type/retrofit control combinations, the following RD&D efforts are needed.

• Research efforts on Hg speciation and capture should be continued. These efforts will include bench- and pilot-scale investigations on the effects of flue gas composition, fly ash properties (UBC content and catalytic metal content), flue gas quench rates, and other important parameters. Speciation and capture computer models must be developed to evaluate field test results and for application to other utility sites.

• Development and demonstration of low cost sorbents, impregnated sorbents and innovative sorbents that are effective in controlling Hg emissions from subbituminous coal and lignite should continue. High temperature sorbents for use with HS-ESPs also should be investigated.

• Development and demonstration of techniques to improve Hg capture in units equipped with an ESP, SDA/ESP or SDA/FF and burn subbituminous coal and lignite is needed. This will include evaluation of coal blending, combustion modifications, use of oxidizing reagents, and use of impregnated sorbents.

• Evaluation and demonstration of cost-effective ESP retrofit approaches including installation of ducting to increase residence times and use of circulating fluidized bed absorbers for optimal utilization of sorbents should be conducted. The use of multipollutant sorbents that capture SO2 and Hg should also be investigated.

• Determination and demonstration of optimum design and operating conditions for COHPAC applications on a range of boiler operating conditions is needed. This will include evaluation of the effects of air-to-cloth ratios, fabric filter material, cleaning frequencies, and baghouse arrangements on Hg capture. COHPAC-based tests should be conducted with both mercury and multipollutant sorbents.

• Continued evaluation of potential leaching or re-emission of mercury from sorbent/ash residues that are disposed of or utilized is needed.

0 comments:

Post a Comment