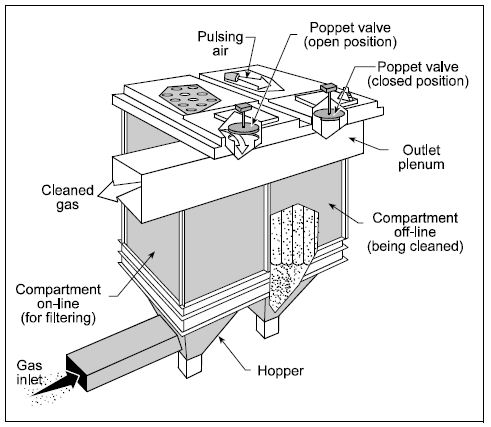

Pulse-jet baghouses can also be compartmentalized. In this case poppet valves located in the clean air plenum are used to stop the flow of dirty air into the compartment. Each compartment can be equipped either with a single pulse valve that supplies compressed air to the group of bags, or have separate pulsing valves that direct pulsing air into the blow pipes above the bag rows in the compartment. During the cleaning cycle the poppet valve closes, stopping the air flow through the compartment. The pulse valve opens for about 0.1 second, supplying a burst of air into the bags for cleaning. The compartment remains off-line for approximately 30 seconds, although this time period can be longer or shorter if desired. The poppet valve then automatically reopens, bringing the compartment back on stream. Alternate compartments are cleaned successively until all the bags in the baghouse have been cleaned (Figure 1). The cleaning cycle in each compartment lasts about 40 to 120 seconds. This cleaning is called off-line cleaning. It is frequently used on fabric filters installed on coal-fired boilers and municipal waste incinerators, allowing very thorough bag cleaning while the baghouse continuously achieves very low emission levels (less than 0.015 gr/dscf).

Fig. 1 Compartmentalized pulse-jet baghouse (plenum-pulse

baghouse)

Thank you for your information about Pulse Jet Bag Filter Manufacturers Chennai.

ReplyDeleteWhen choosing the equipment for flue gas cleaning it is important, that the dimensions of the chosen installation correspond to the type of fuel used

ReplyDeleteGreat Post! Thanks for sharing such beautiful information with us. Please keep sharing.

ReplyDeleteIndustrial Dust Extraction System

Fume Extraction System

Dust Extraction Installation

Welding Air Filtration Systems

Industrial Air Conditioning Adelaide