Sulfur Dioxide Control Technologies

Two commercially available Flue Gas Desulfurization (FGD) technology

options for removing the SO2 produced by coal-fired power plants are offered in

EPA Base Case v.4.10: Limestone Forced Oxidation (LSFO) — a wet FGD technology —

and Lime Spray Dryer (LSD) — a semi-dry FGD technology which employs a spray

dryer absorber (SDA). In wet FGD systems, the polluted gas stream is brought

into contact with a liquid alkaline sorbent (typically limestone) by forcing it

through a pool of the liquid slurry or by spraying it with the liquid. In dry

FGD systems the polluted gas stream is brought into contact with the alkaline

sorbent in a semi-dry state through use of a spray dryer. The removal

efficiency for SDA drops steadily for coals whose SO2 content exceeds 3lb SO2/MMBtu,

so this technology is provided only to plants which have the option to burn

coals with sulfur content no greater than 3 lbs SO2/MMBtu. In EPA Base

Casev.4.10 when a unit retrofits with an LSD SO2 scrubber, it loses the option

of burning BG, BH, and LG coals due to their high sulfur content. In EPA Base

Case v.4.10 the LSFO and LSD SO2 emission control technologies are available to

existing "unscrubbed" units. They are also available to existing

"scrubbed" units with reported

removal efficiencies of less than fifty percent. Such units are

considered to have an injection technology and classified as “unscrubbed” for

modeling purposes in the NEEDS database of existing units which is used in

setting up the EPA base case. The scrubber retrofit costs for these units are

the same as regular unscrubbed units retrofitting with a scrubber. Scrubber

efficiencies for existing units were derived from data reported in EIA Form

767. In transferring this data for use in EPA Base Case v.4.10 the following

changes were made. The maximum removal efficiency was set at 98% for wet

scrubbers and 93% for dry scrubber units. Existing units reporting efficiencies

above these levels in Form 767 were assigned the maximum removal efficiency in

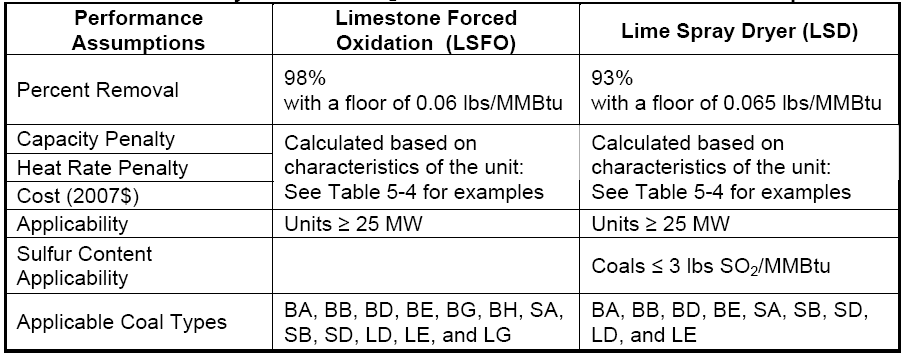

NEEDS v.4.10 indicated in the previous sentence. As shown in Table 1, existing

units that are selected to be retrofitted by the model with scrubbers are given

the maximum removal efficiencies of 98% for LSFO and 93% for LSD. The procedures

used to derive the cost of each scrubber type are discussed in detail in the

following sections. Potential (new) coal-fired units built by the model are

also assumed to be constructed with a scrubber achieving a removal efficiency

of 98% for LSFO and 93% for LSD. In EPA Base Case v.4.10 the costs of potential

new coal units include the cost of scrubbers.

Table 1. Summary of Retrofit SO2 Emission Control Performance Assumptions

Methodology for

Obtaining SO2 Controls Costs

The Sargent and Lundy update of SO2 and NOx control costs is notable

on several counts. First, it brought costs up to levels seen in the marketplace

in 2009. Incorporating these costs into EPA’s base case carries an implicit

assumption, not universally accepted, that the run up in costs seen over the

preceding 5 years and largely attributed to international competition, is

permanent and will not settle back to pre-2009 levels. Second, a revised

methodology, based on Sargent and Lundy’s expert experience, was used to build

up the capital, fixed and variable operating and maintenance components of

cost. That methodology, which employed an engineering build up of each

component of cost, is described here and in the following sections. respectively.

Capital Costs: In building up capital costs three separate cost modules were

included for LSD and four for LSFO: absorber island, reagent preparation, waste

handling (LSFO only), and everything else (also called “balance of plant”) with

the latter constituting the largest cost module, consisting of fans, new wet

chimney, piping, ductwork, minor waste water treatment, and other costs required

for treatment. For each of the four modules the cost of foundations, buildings,

electrical equipment, installation, minor, physical and chemical wastewater

treatment, and average retrofit difficulty were taken into account.

The governing cost variables for each module are indicated in Table 2.

The major variables affecting capital cost are unit size and the SO2 content of

the fuel with the latter having the greatest impact on the reagent and waste

handling facilities. In addition, heat rate affects the amount of flue gas

produced and consequently the size of each of the modules. The quantity of flue

gas is also a function of coal rank since different coals have different

typical heating values.

Once the key variables that figure in the cost of the four modules are

identified, they are used to derive costs for each base module in equations

developed by Sargent and Lundy based on their experience with multiple

engineering projects. The base module costs are summed to obtain total bare

module costs. This total is increased by 30% to account for additional

engineering and construction fees. The resulting value is the capital,

engineering, and construction cost (CECC) subtotal. To obtain the total project

cost (TPC), the CECC subtotal is increased by 5% to account for owner’s home

office costs, i.e., owner’s engineering, management, and procurement costs. The

resulting sum is then increased by another 10% to build in an Allowance for

Funds used During Construction (AFUDC) over the 3-year engineering and

construction cycle. The resulting value, expressed in $/kW, is the capital cost

factor that is used in EPA Base Case v.4.10.

Table 2.Capital Cost Modules and Their Governing Variables for SO2 and NOx Emission Controls

Variable Operating and

Maintenance Costs (VOM): These are the costs

incurred in running the emission control device. They are proportional to the

electrical energy produced and are expressed in units of $ per MWh. For FGD,

Sargent and Lundy identified four components of VOM: (a) costs for reagent

usage, (b) costs for waste generation, (c) make up water costs, and (d) cost of

additional power required to run the control (often called the “parasitic load”).

For a given coal rank and a pre-specified SO2 removal efficiency, each of these

components of VOM cost is a function of the generating unit’s heat rate

(Btu/kWh) and the sulfur content (lb SO2/MMBtu) of the coal (also referred to

as the SO2 feed rate). For purposes of modeling, the total VOM includes the

first three of these component costs. The last component – cost of additional

power – is factored into IPM, not in the VOM value, but through a capacity and

heat rate penalty as described in the next paragraph. Due to the differences in

the removal processes, the per MWh cost for waste handling, makeup water, and

auxiliary power tend to be higher for LSFO while reagent usage cost and total

VOM (excluding parasitic load) are higher for LSD.

Capacity and Heat Rate

Penalty: The amount of electrical power required to

operate the FGD device is represented through a reduction in the amount of

electricity that is available for sale to the grid. For example, if 1.6% of the

unit’s electrical generation is needed to operate the scrubber, the generating

unit’s capacity is reduced by 1.6%. This is the “capacity penalty.” At the same

time, to capture the total fuel used in generation both for sale to the grid

and for internal load (i.e., for operating the FGD device), the unit’s heat

rate is scaled up such that a comparable reduction (1.6% in the previous

example) in the new higher heat rate yields the original heat rate28. The factor

used to scale up the original heat rate is called “heat rate penalty.” It is a

modeling procedure only and does not represent an increase in the unit’s actual

heat rate (i.e., a decrease

in the unit’s generation efficiency). Unlike previous base cases,

which assumed a generic heat rate and capacity penalties for all installations,

in EPA Base Case v.4.10 specific LSFO and LSD heat rate and capacity penalties

are calculated for each installation based on equations developed by Sargent

and Lundy that take into account the rank of coal burned, its SO2 rate, and the

heat rate of the model plant.

Fixed Operating and

Maintenance Costs (FOM): These are the annual

costs of maintaining a unit. They represent expenses incurred regardless of the

extent to which the emission control system is run. They are expressed in units

of $ per kW per year. In calculating FOM Sargent and Lundy took into account

labor and materials costs associated with operations, maintenance, and administrative

functions. The following assumptions were made:

Mathematically, the relationship of the heat rate and capacity

penalties (both expressed as positive percentage values) can be represented as

follows:

- FOM for operations is based on the number of operators needed which is a function of the size (i.e., MW capacity) of the generating unit and the type of FGD control. For LSFO 12 additional operators were assumed to be required for a 500 MW or smaller installation and 16 for a unit larger than 500 MW. For LSD 8 additional operators were assumed to be needed.

- FOM for maintenance is a direct function of the FGD capital cost

- FOM for administration is a function of the FOM for operations and maintenance.

Table 3 presents the capital, VOM, and FOM costs as well as the

capacity and heat rate penalty for the two SO2 emission control technologies

(LSFO and LSD) included in EPA Base Case v.4.10 for an illustrative set of

generating units with a representative range of capacities and heat rates.

Table 3. Illustrative Scrubber Costs (2007$) for Representative Sizes and Heat Rates under the Assumptions in EPA Base Case v.4.10

0 comments:

Post a Comment